Manufacturer of high rigidity hard rail line rail turning center machine tools

Turning center CNC machine tool is a high-precision, high-efficiency automatic machine tool, equipped with multi-station turret or power turret, so that the machine tool has a wide range of technological performance, and can process straight cylinders, oblique cylinders, arcs and various threads , grooves, worms, hardware parts and other complex workpieces, and have played a good high-speed, high-precision, high-efficiency economic effect in the mass production of complex parts. In short, the turning center CNC machine tool is a compound turning machine tool.

After increasing the functions of power milling, drilling, boring, and sub-spindle, the process of secondary and tertiary processing of parts required by the car can be completed on the CNC machine tool of the turning center at one time, and the tool change speed is fast and the processing time is short. The preferred CNC machine tool for parts product processing.

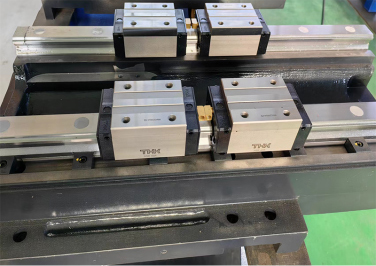

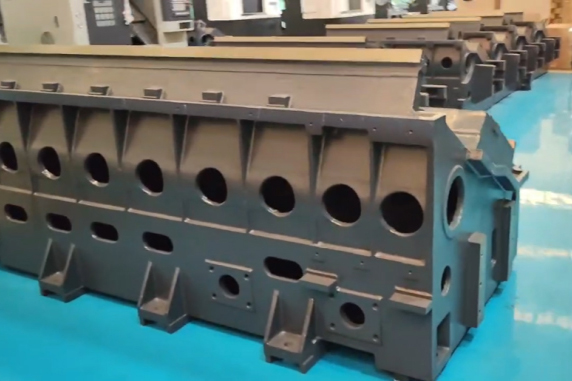

Qingdao Taizheng Precision Machinery Co., Ltd. "Taishu Precision Machine" brand full range of CNC machine tools for turning centers are divided into hard rail turning centers and line rail turning centers. Rigid rails, also known as box rails, are a solid design with hardened and ground surfaces that provide excellent rigidity and support. Rigid rail systems consist of metal sliding surfaces and lubrication channels. To ensure smooth motion, it is usually the first choice for heavy-duty machining operations that require high load capacity and stability. Linear guideways utilize a series of rollers to achieve precise linear motion, with low friction and high-speed capabilities, suitable for fast movement and precise positioning turning center. The whole machine adopts an inclined layout, and the bed body is a tubular hollow structure, which greatly improves the bending and torsional rigidity of the machine tool during work. At the same time, after two aging treatments, the stability of the machine tool is improved. High rigidity and high stability of the bed Guarantee the high precision of the whole machine. The main shaft is an independent main shaft unit equipped with special bearings for high-precision main shaft. The whole main shaft unit has small thermal deformation and strong thermal stability. The feed system is all directly driven by servo motors, with good rigidity and dynamic characteristics. At the same time, it is equipped with Taiwan brand servo turret, with fast tool change speed and high repeat positioning accuracy. It can be assembled with multiple stations, which is convenient for multi-process workpiece processing. Tailstock cover The cylinder is driven by hydraulic pressure, which saves time and effort. At the same time, it is equipped with a mobile positioning mutual rotation device to prevent misoperation. Provide safety guarantee for users during operation

The whole series of turning center CNC machine tools of the "Taishu Precision Machine" brand adopts Taiwan's original drawings and process standards. Each part adopts the Meehanite casting process, and the casting number is HT300. The whole is 45°, and the bed parts are cold-processed on the main machine of the CNC gantry pentahedron machining center; the head box parts are cold-processed on the production line of the high-precision bedroom machining center, and the guide rail surface of the bed column is passed through the Wadrixi CNC gantry guide rail. The production line is completed at one time. In order to strictly control the quality of the turning center parts, all small and medium parts on the CNC machine tools of the turning center are all precisely processed by our company. There are 3 high-precision parts working machine production lines to ensure the uniformity and standardization of the turning center parts. Sex, interchangeability, improve the efficiency for precision assembly.

"Taishu Precision Machine" turning center, the advantages of high-speed, high-precision, and powerful cutting:

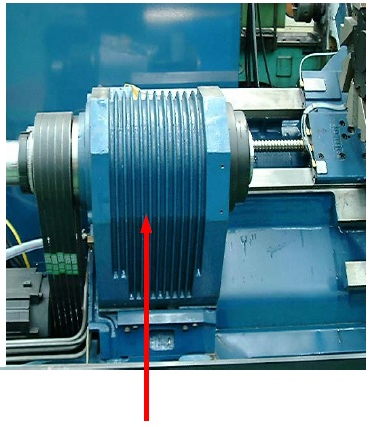

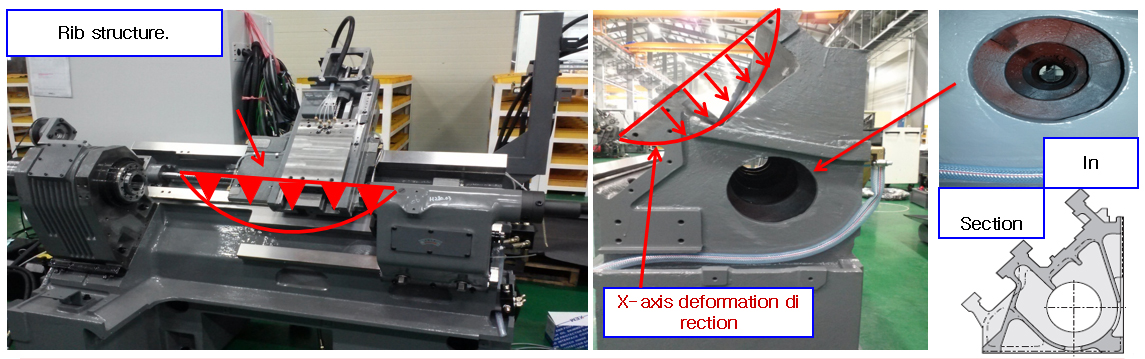

1. The machine tool minimizes thermal deformation. The symmetrical structure of the main shaft and the heat sink, the heat generated when the main shaft rotates produces fine thermal deformation, the asymmetrical structure is a deformation in one direction, and the symmetrical structure of the main shaft box spreads and diffuses to the center of the main shaft, thus reducing the minimum precision deformation.

2. The casting structure of the whole machine body, double-set pipe tunnel and bridge rib structure are added to the lattice rib of the lathe bed, which can control the cutting and impact force, improve precision machining and high rigidity.

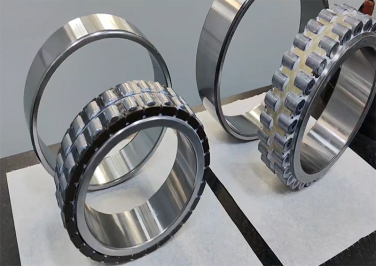

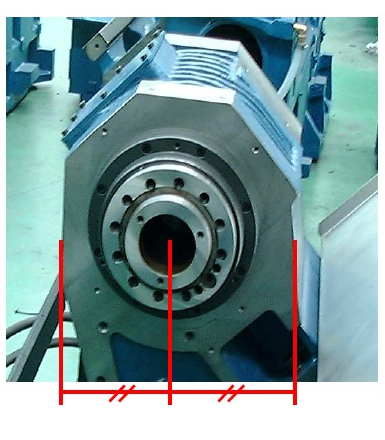

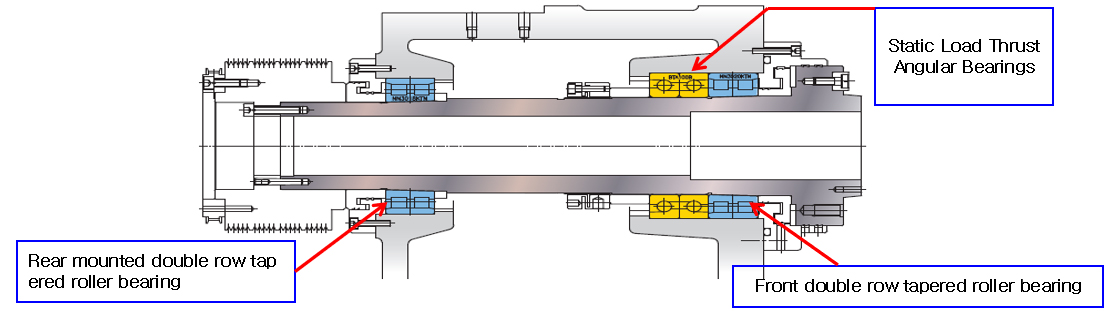

3.The structure of the main shaft of the machine tool is one of the important factors for powerful cutting. One end of the main shaft of the turning center adopts a front double-row tapered roller bearing and a supporting double-row thrust angular contact surface bearing. Such a unique main shaft structure is suitable for high-load cutting. , The deformation of the drilling hole is reduced to a minimum

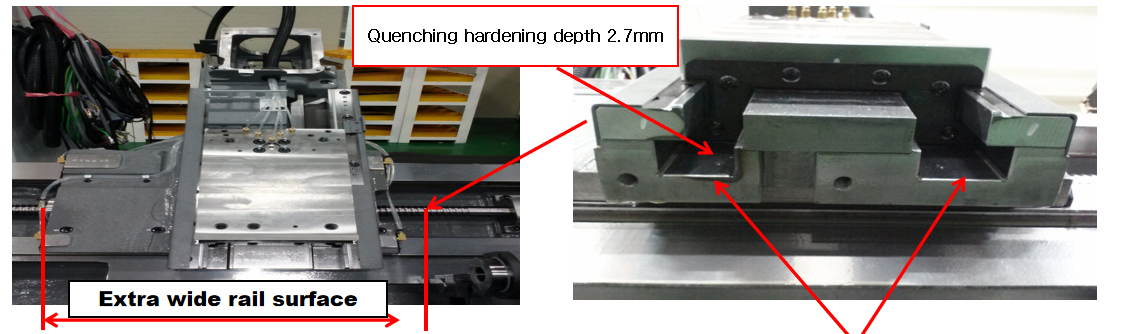

4. The super-wide guide rail cross slider adopts six-sided constraint inner frame slide rail, the width of the guide surface of the slide seat is 1.2 times that of similar products, and the surface high-frequency quenching depth reaches 2.7mm, which is 2 times that of similar products 1.3mm. When the machine tool is impacted in the working state, it can maintain complete and unchanged precision and prolong the service life of the machine tool.

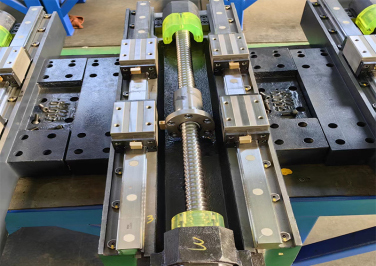

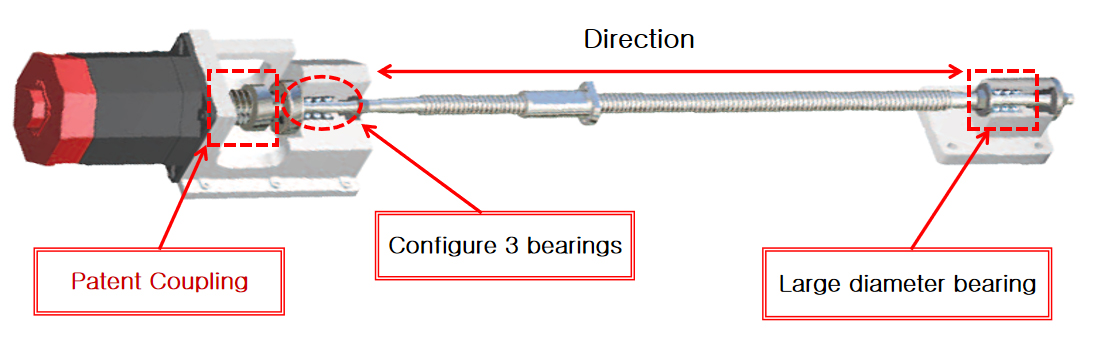

5. The unique installation method of the screw, bearing and coupling realizes the smallest thermal displacement, adopts the precision power coupling that completely eliminates the distortion in the radial direction, eliminates the gap, and realizes high responsiveness. The ball screw is installed at both ends 5 A large-diameter bearing will eventually pre-relay the load to the bearings supported at both ends, so that the bearings can evenly distribute the load force, so as to maintain the life and precision of the machine.

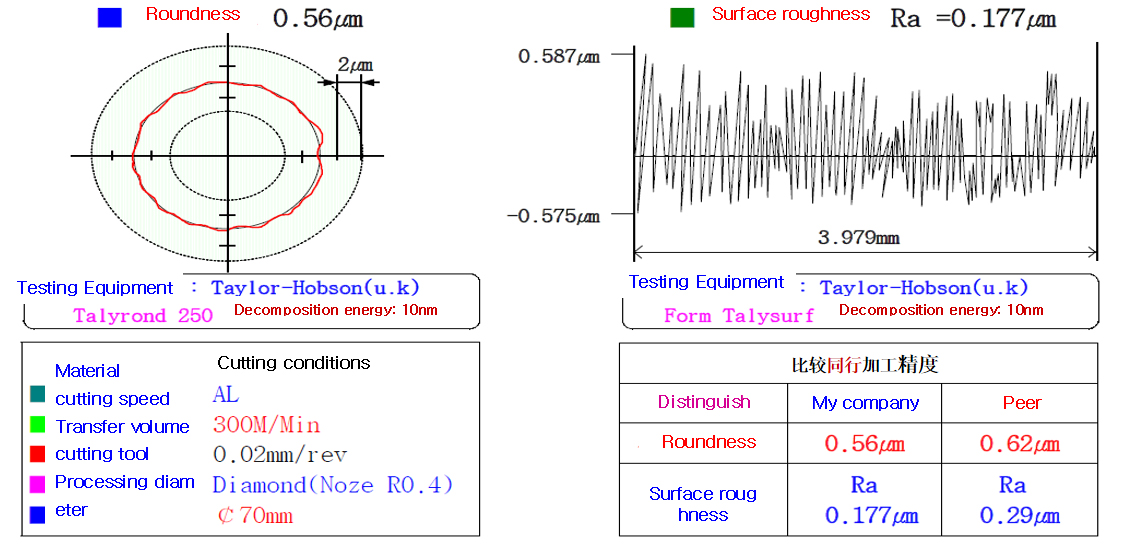

6.Machining accuracy test results

Qingdao Taizheng Precision Machinery Co., Ltd. has a full range of vertical machining center products, pursues a brand-creating, high-grade quality strategy, has won the national high-tech enterprise, "specialized, special and new" enterprise, and obtained the ISO9001 quality management system of the CQC review agency Certification, the products are sold well all over the country and exported to many countries and regions because of their stable performance, reliable quality and high cost performance.